What Does A Three-Legged Stool Have To Do With A Pipeline Route?

I spent a good part of my childhood growing up on a farm in West Virginia, both on our farm and my grandparents’ farms. We had friends down the road who had a small herd of Guernsey cattle that they would milk, by hand, twice a day (this was the late 50’s and early 60’s). Milking was quite an interesting process for the outsider (me) to watch as, in this case, the farmer, his older children, and a helper worked diligently to milk all the cattle as quickly as possible. Cattle were brought into the barn, milked, and then lead out like clockwork. One of the simplest (but essential) tools used in the milking process was a three-legged stool.

I spent a good part of my childhood growing up on a farm in West Virginia, both on our farm and my grandparents’ farms. We had friends down the road who had a small herd of Guernsey cattle that they would milk, by hand, twice a day (this was the late 50’s and early 60’s). Milking was quite an interesting process for the outsider (me) to watch as, in this case, the farmer, his older children, and a helper worked diligently to milk all the cattle as quickly as possible. Cattle were brought into the barn, milked, and then lead out like clockwork. One of the simplest (but essential) tools used in the milking process was a three-legged stool.

There are hundreds of jokes on why milkers use three-legged stools. “Why does a milker’s stool only have three legs? Because the cow has the udder!” is a joke I learned in grade school. The REAL answer is stability.

One or two-legged stools give some level of stability on uneven floors. However, they do tip over when left on their own. A four-legged stool will not tip over. However, it will never be stable on an uneven floor (always balancing on three legs). A three-legged stool will not tip over and provides stability to the milker.

So again, what does a three-legged stool have to do with picking a pipeline route?

An optimum route (for both capital cost and schedule) will always sit on a three-legged stool consisting of the following perspectives:

- Engineering/Constructability

- Right-of-Way

- Environmental

It is up to the pipeline owner (our client) to determine the priority between capital costs and schedules (as time is money). Stating the obvious, if there is plenty of time to complete the project, capital costing will generally determine the optimum route. However, when the schedule is critical, some concessions may need to be made regarding routing and construction methodologies to secure ROW and permitting and meet the schedule.

CAPITAL COST:

As a Rule of Thumb, Capital Project Cost for a cross-country pipeline can be broken into four main buckets:

These costs are all interdependent, with route selection being the biggest factor affecting, in one way or another, over 90% of a pipeline installation cost.

Material

Specifically, the wall thickness (and coating) of the pipeline (the largest material cost for a cross-country pipeline) will be determined not only by hydraulics but also by:

- the proximity of the route to homes, churches, stores, and other places where people meet

- the presence of electric transmission lines

- construction methods used for installation

- and stakeholder (landowner and regulatory) requirements.

Simply, the more congested the route or, the more stressful the installation, the thicker the pipe wall. The thicker the pipe wall, the higher the cost/foot for pipe. This same rule applies to pipe coatings, where Abrasion Resistant Outerwrap (ARO) is added to the coating (due to construction methods, rocky soil, and other factors), making the coating more expensive.

Construction

Construction Costs are affected by the pipe wall thickness. Specifically, welding can be as much as 30% of construction costs, and thicker wall pipe increases welding costs. Other factors affecting construction costs are terrain, soil type; route congestion and clearing requirements; and construction methods required at crossings and through Environmentally Sensitive Areas (ESA’s). All these factors are controlled by the route selected.

Right of Way and Environmental

ROW Costs are absolutely dictated by land values along the route selected, while Environmental Costs are based on where the pipeline can be installed around or through ESA’s. Regarding the latter, pipeline routing must look at the three levels of dealing with ESA’s. These levels are “Avoid,” “Minimize,” and “Mitigate.” The higher the level in dealing with ESA’s, the more expensive the Environmental Costs of the project. The route selected directly controls ROW costs and costs associated with Environmental considerations.

Engineering, Surveying and Inspection Service

Engineering, Surveying, and Inspection Service costs are directly affected by all the factors mentioned above. A more complex design, discussions with landowners and regulatory agencies, and a longer construction duration increase these costs exponentially.

All 3 legs are needed to stand.

There are numerous examples where the path of least resistance or lowest capital cost route from only the Engineering/Constructability, Right-of-Way, or Environmental perspectives individually will not translate into the lowest capital cost route for the new pipeline. A route selected from two of the three perspectives ensures a better overall project capital cost but again does not always lead to an optimum cost. It is important that all three perspectives are considered when selecting a new pipeline route.

SCHEDULE:

Construction duration is important. However, ROW acquisition and securing federal, state, and local permits have become the longest lead items in a capital project schedule (even exceeding material deliveries in many cases). Both ROW acquisition and permit approval are directly related to the route selected and the method of constructing a pipeline.

Many pipeline companies have the Right of Eminent Domain, allowing the company to condemn land for their ROW. However, there is a great reluctance to use this right as it is important to maintain good relations with landowners, and implementation is costly and time-consuming.

Consequently, openly negotiating with landowners is the key to success with re-routes onto landowners more receptive (or less objectionable) to the pipeline route being frequent. Obviously, the more landowners encountered along a route, the more difficult ROW acquisition becomes.

Just as they were for Environmental Costs, the Environmental Schedule is based on where the pipeline can be installed around or through ESA’s. Pipeline routing must look at the three levels of dealing with ESA’s. These levels are “Avoid,” “Minimize,” and “Mitigate.” The higher the level in dealing with ESA’s, the more difficult (and the longer the duration) Environmental permits are to secure.

Does your stool stand?

It is up to the pipeline owner to determine the priority between capital costs and schedule. Once the priority is selected, it is important to consider three main perspectives to arrive at an optimum route selection. Those perspectives are:

- Engineering/Constructability

- Right-of-Way

- Environmental

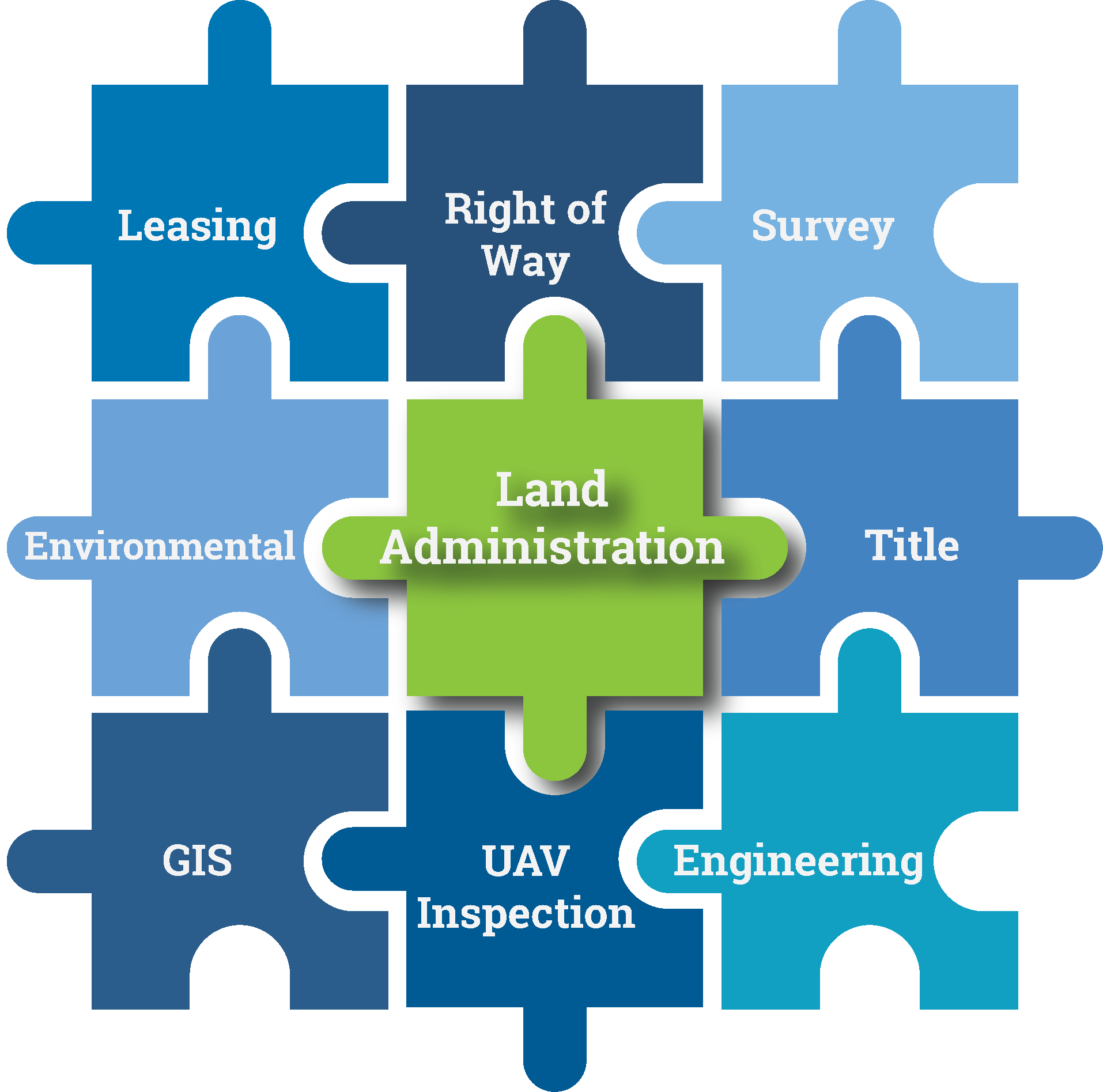

Approaching route selection using the three-legged stool style of analysis will optimize the route cost and installation schedule. Can your land services provider help you select the best route? Percheron has in-house Subject Matter Experts in Engineering, Right of Way, Environmental, and Surveying and is ready to help with your routing needs. Give us a call at 832.300.6400 or email KC at kc.yost@percheronllc.com for more information.

.png?width=750&height=375&name=Percheron-(LARGE).png)